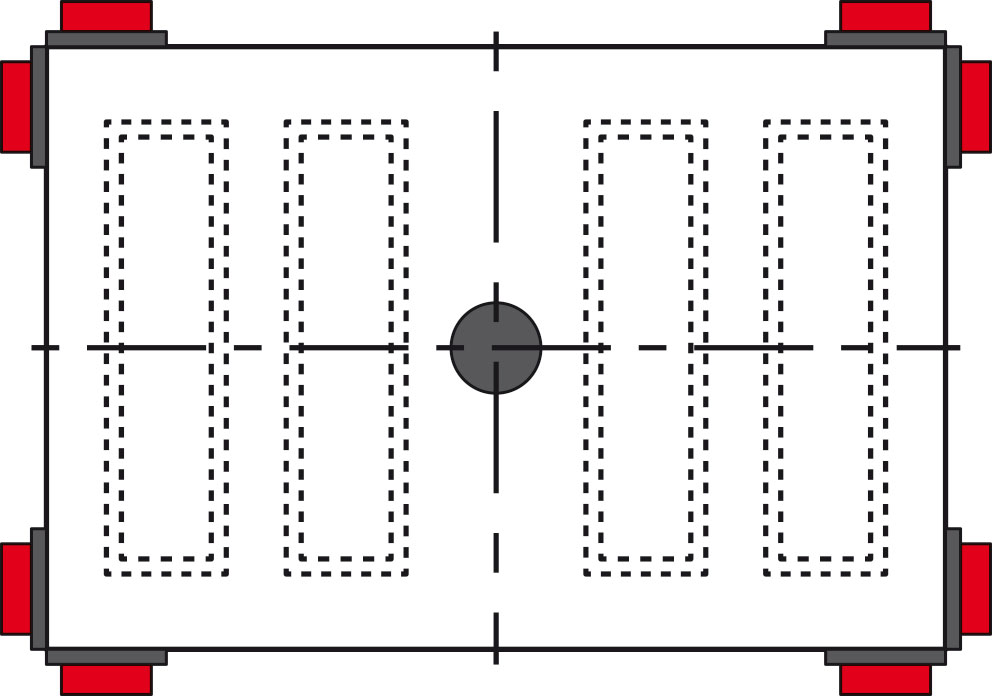

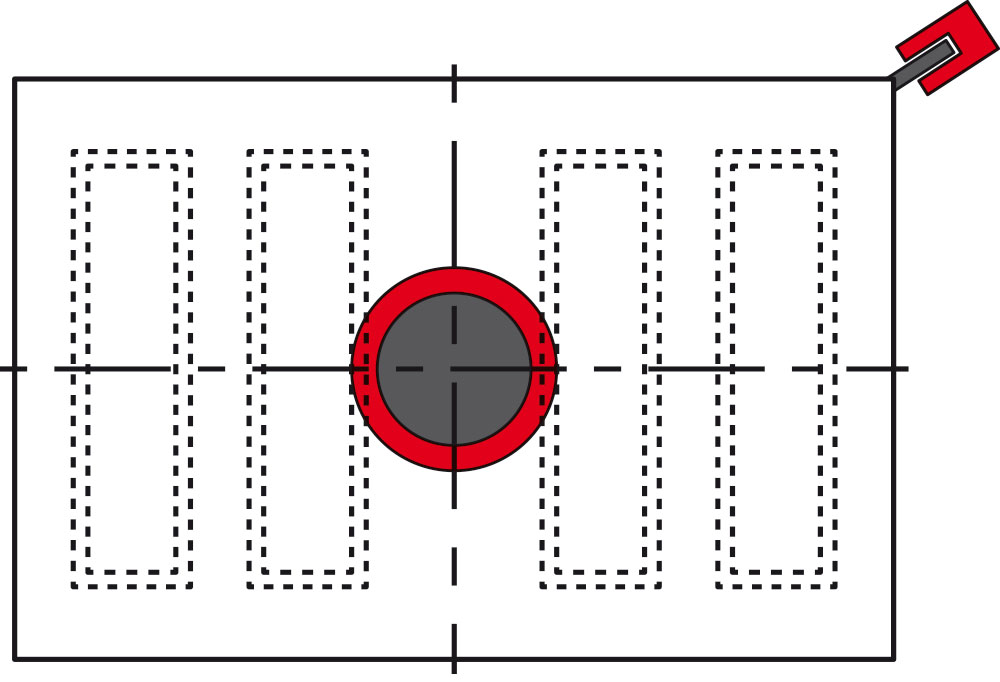

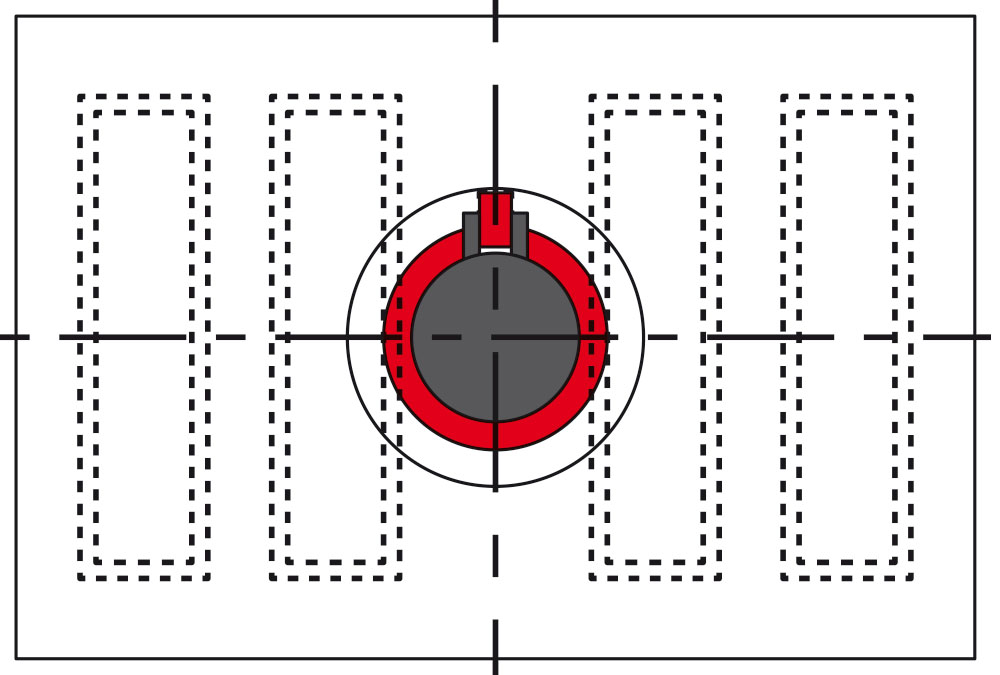

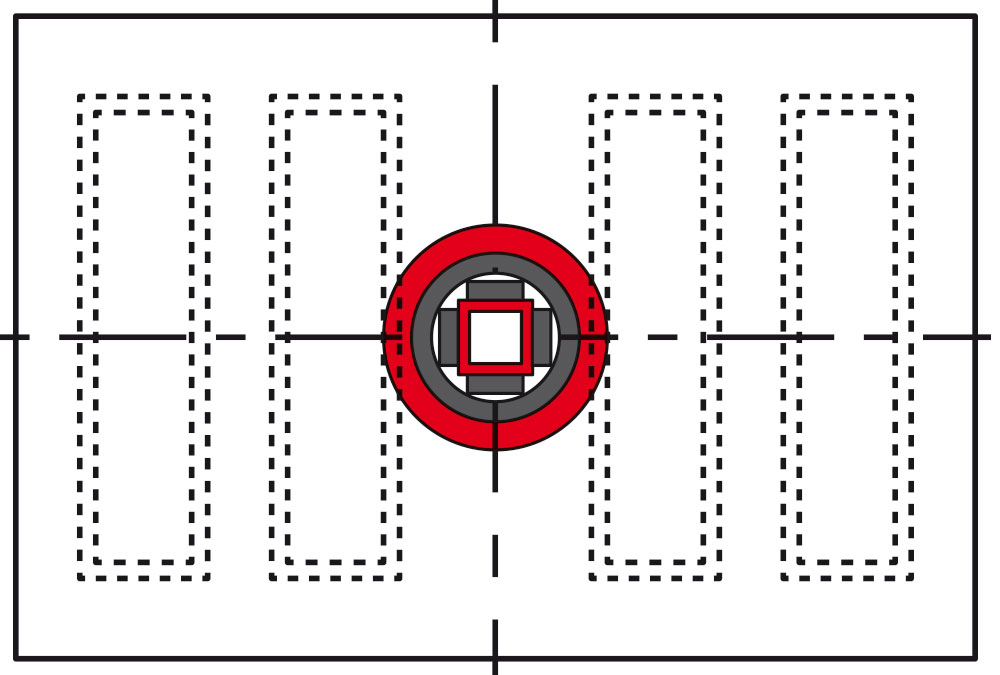

| Single acting cylinder, cardanic suspension in casting pit | Cylinder with head flange and plunger guidance | Cylinder with head flange, plunger guidance and anti-rotation protection | Double acting cylinder with head flange, rod guidance and anti-rotation protection |

|---|---|---|---|

|  |  |  |

|

|

|

|

| Ceraplate possible! | Ceraplate possible! | Ceraplate possible! | Ceraplate possible! |

| Transducer possible! |

The table gives a overview of thevariety of vertical casting cylinders used. With the exception of the cardanic suspended plunger- casting cylinder, which is still in use in casting plants with external table guidance, all casting cylinders have an integrated, highly precise table guidance and a bending resistant piston rod. The advantage of this solution is due to a minimum possible friction as well as the protection of the entire casting cylinder guidance. This modern casting cylinder construction can be supplied with or without integrated anti- rotation protection.

By application, in which the plunger and table weight is not enough to ensure a minimum starting pressure, differential type casting cylinders of can be used. Through the annulus pressure, a uniformly controlled retraction can be ensured from the load free starting position to the maximum table weight. Of course, the casting cylinders of the differential cylinder construction type also have an integrated rod guidance with bending resistant construction of the piston rod as well as an integrated anti- rotation protection over the entire stroke.

Crusher Open Pit Mine Yimin He (CN)

Crusher Open Pit Mine Yimin He (CN) Hunger Hydraulic Cylinders for NASA Crawler Transporter

Hunger Hydraulic Cylinders for NASA Crawler Transporter Hydraulic cylinder for 8000 ton offshore joint test rig

Hydraulic cylinder for 8000 ton offshore joint test rig Hydraulic cylinder for aluminium casting machine

Hydraulic cylinder for aluminium casting machine Hydraulic cylinder for Canary wharf bridge in London

Hydraulic cylinder for Canary wharf bridge in London Hydraulic cylinder for Offshore Piling Barge

Hydraulic cylinder for Offshore Piling Barge Hydraulic cylinders and power packs for coal ship unloader Huilai lll

Hydraulic cylinders and power packs for coal ship unloader Huilai lll Hydraulic cylinders for flood protection dam St. Petersburg

Hydraulic cylinders for flood protection dam St. Petersburg Hydraulic cylinders for Sungcheoun flood protection dam

Hydraulic cylinders for Sungcheoun flood protection dam Hydraulic cylinders for walking platform Seawalker

Hydraulic cylinders for walking platform Seawalker Hydraulic cylinders for wave compensation on oil drill ships and platforms

Hydraulic cylinders for wave compensation on oil drill ships and platforms Hydraulic cylinders for wave energy plant Oyster I and Oyster ll

Hydraulic cylinders for wave energy plant Oyster I and Oyster ll Hydroelectric Power Plant Rheinfelden

Hydroelectric Power Plant Rheinfelden